3860

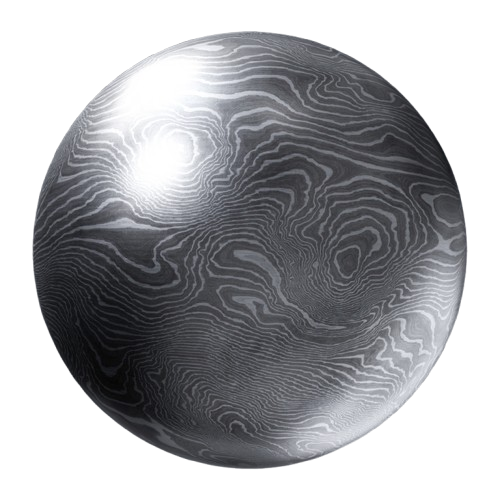

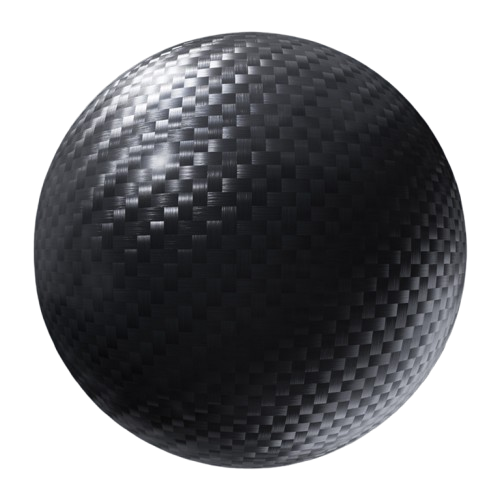

Unset Carbide

For highly efficient sawing of difficult-to-machine and abrasive materials. This unset carbide band saw blade is particularly suitable for abrasive materials such as Inconel and titanium.

• Unset band saw blade with positive rake angle

• Unset teeth for best surface finish

• High quality of backing material and carbide tips for best cutting performance and long service life

• Ground tooth tips for sharp cutting edges, especially important when sawing titanium

• High heat resistance for fast sawing even in large workpieces

The 54 mm and 67 mm TMC bandsaw blades are supplied in a coated version. The coating allows you to work at a higher band speed and feed rate.

• Extremely high cutting performance

• Increased tool life

• High resistance to high temperatures

Other dimensions and qualities available on request.

TCD is for sawing difficult and abrasive materials.

• Un set bandsaw blade with positive rake angle

• Specially developed multi-span design for highest cutting performance in titanium alloys

• Also suitable for stainless steels and aluminium

• Unset teeth for best surface finish and long service life

• Extra wide set on blades with W in end

TCZ is developed for sawing both chrome plated and case hardened bars.

• Also suitable for non-metallic materials, e.g. graphite, which does not form chips when sawing

• Excellent resistance of the teeth

• Long tool life

TCA is a special band saw blade for aluminium.

• Un set band saw blade with positive rake angle

• Specially developed for cutting aluminium, also for large blocks

• Can also be used in foundries with CNC automatic saws

• Extended band life

• Better surface finish of the cut

WOOD

METAL

ADVANCED

Catalogue Pages

Variations

_id

profile

pitch

gauge

width

BA6041131-4-2TMC

TMC

1.4-2

1.3

41

BA6041132-3TMC

TMC

2-3

1.3

41

BA6054131-4-2TMC

TMC

1.4-2

1.3

54

BA6054132-3TMC

TMC

2-3

1.3

54

BA6054161-1-25TMC

TMC

1-1.25

1.6

54

BA6054161-4-2TMC

TMC

1.4-2

1.6

54

BA6054162-3TMC

TMC

2-3

1.6

54

BA6067161-1-25TMC

TMC

1-1.25

1.6

67

BA6067161-4-2TMC

TMC

1.4-2

1.6

67

BA6067162-3TMC

TMC

2-3

1.6

67

BA6080161-1-25TMC

TMC

1-1.25

1.6

80

BA6080161-4-2TMC

TMC

1.4-2

1.6

80

BA6080160-7-1TMC

TMC

0.7-1

1.6

80

BA60100111-4-2TMC

TMC

1.4-2

1.1

100

BA6027093-4TCD

TCD

3-4

0.9

27

BA6027093TCD

TCD

3

0.9

27

BA6034112-3TCD

TCD

2-3

1.1

34

BA6034113-4TCD

TCD

3-4

1.1

34

BA6041131-4-2TCD

TCD

1.4-2

1.3

41

BA6041131-9-2-1TCD

TCD

1.9-2.1

1.3

41

BA6041132-3TCD

TCD

2-3

1.3

41

BA6041133-4TCD

TCD

3-4

1.3

41

BA6054161-4-2TCD

TCD

1.4-2

1.6

54

BA6054161-9-2-1TCD

TCD

1.9-2.1

1.6

54

BA6054162-3TCD

TCD

2-3

1.6

54

BA6054163-4TCD

TCD

3-4

1.6

54

BA6067161-1-25TCD

TCD

1-1.25

1.6

67

BA6067161-4-2TCD

TCD

1.4-2

1.6

67

BA6080160-5-0-8TCD

TCD

0.5-0.8

1.6

80

BA6027093-4TCZ

TCZ

3-4

0.9

27

BA6034112-3TCZ

TCZ

2-3

1.1

34

BA6034113-4TCZ

TCZ

3-4

1.1

34

BA6041132-3TCZ

TCZ

2-3

1.3

41

BA6041133-4TCZ

TCZ

3-4

1.3

41

3850

Top Fabricator

Browse all Products